Eesti disain ja kvaliteet meie Tartumaa tehasest

Täna päike, homme vihm, ülehomme lumi ja jää – nagu põhjamaine inimene, on ka meie kümblustünnid pidevateks muutusteks alati valmis. Just seetõttu me disainime, arendame ja valmistame oma tooted ise. Kauneimad kümblustünnid ja kõige luksuslikumad terrassivannid valmivad Tartu vallas, Kõrenduse külas ja seda täpselt vastavalt teie soovidele. Tulge meile külla ja teeme teile hea meelega tehases ringkäigu!

Ainulaadne kooslus

Tänaseks on meie tehases kogu armastuse ja tähelepanu pälvinud küll kümblustünnid ja terrassivannid, kuid see pole olnud alati nii. Meie esimesed 15 tegevusaastat olid samaväärselt kümblustünnidele pühendatud ka paatide ja kaatrite ehitamisele, et luua kvaliteetaja veetmise võimalusi ka vee peal. Selle aja jooksul arendasime välja ja tootsime igapäevaselt lisaks oma võrratutele kümblustünnidele ka kauneid Lingalaid paate. Elavaid legende nagu Lingalaid 530, Lingalaid P6 ja Lingalaid 403 võib kohata sisevetel ja rannikumerel nii Eestis, kui kaugemalgi.

Aastatepikkused kogemused veesõidukite ehitamise valdkonnas, kus kvaliteedi, töökindluse ja turvalisuse poolelt kompromisse ei tehta, on aidanud meil arendada välja ainulaadse koosluse tehnilistest kompetentsidest. See hõlmab klaasplasti ja muude komposiitmaterjalide tootmise ja töötlemise süviti tundmist, tisleritöö ja puidutehnoloogia valdamist kõrgemal tasemel, põhjalikke teadmisi elektri- ja elektroonikaseadmetest ning sellest, kuidas see kõik märjas keskkonnas kauakestva ja töökindlana toimima panna.

Koostöö on arengu alus ja pidev areng on meie jaoks väga oluline. Seetõttu on ka meie koostööpartnerid ja komponentide tarnijad valitud erilise hoolega. Need on oma ala tipud, eranditult maailmatasemel tunnustatud ettevõtted – innovaatorid, kelle toodete kõrges kvaliteedis ja spetsialistide kompetentsis oleme sama kindlad, kui enda omas.

Kogemused, kompetents, koostöö ja areng

- Meie koostööpartneriteks ja tarnijateks on maailmatasemel tunnustatud turuliidrid kvaliteedi ja innovatsiooni poolest

- Meie arendus- ja tootmistiimil on ainulaadne kooslus kompetentsidest komposiitide-, puidutehnoloogia- ja elektroonikavaldkonnas

- Meie meeskond, meie tooted ja meie ettevõte on järjepidevas arengus – iga päevaga vähemalt 1% võrra eilsest parem

Süsteemsus igal sammul

Iga kümblustünn valmib meie tehases justkui rätsepaülikonnana. See liigub oma sünniprotsessi käigus 2500 ruutmeetrisel tootmispinnal ühest tööjaamast teise, kus iga erineva etapi eest kannavad hoolt oma ala spetsialistid. Siin pole mitte ükski tegevus juhuslik ja iga samm sünnib ainult parimatele, praktikas kvaliteetset ja töökindlat tulemust andnud võtetele tuginedes.

Kogemused ja pidev areng

Aastatepikkused kogemused veesõidukite ehitamise valdkonnas, kus kvaliteedi, töökindluse ja turvalisuse poolelt kompromisse ei tehta, on aidanud meil arendada välja ainulaadse koosluse tehnilistest kompetentsidest. See hõlmab muuhulgas ka põhjalikke teadmisi elektri- ja elektroonikaseadmetest ning sellest, kuidas see kõik märjas keskkonnas kauakestva ja töökindlana toimima panna. Vaatamata sellele, mida juba teame ja oskame, panustame me järjekindlalt õppimisse, meeskonnaliikmete arengusse ja innovatsiooni, et olla oma töös iga päevaga natuke paremad.

Kui kvaliteedist saab harjumus

Me oleme uhked oma toodete üle. Me ei lepi kunagi keskpärasusega ja püüdleme igal sammul ei vähema, kui täiuslikkuse poole. See ei tule mitte ainult meie kvaliteedijuhtimise süsteemist, pidevalt parendavatest protsessidest ja tehnoloogiast, mida igapäevaselt rakendame. Kõige olulisemaks teguriks siin on töökultuur – kui midagi on võimalik teha täpselt, siis just nii me seda ka teha tahame.

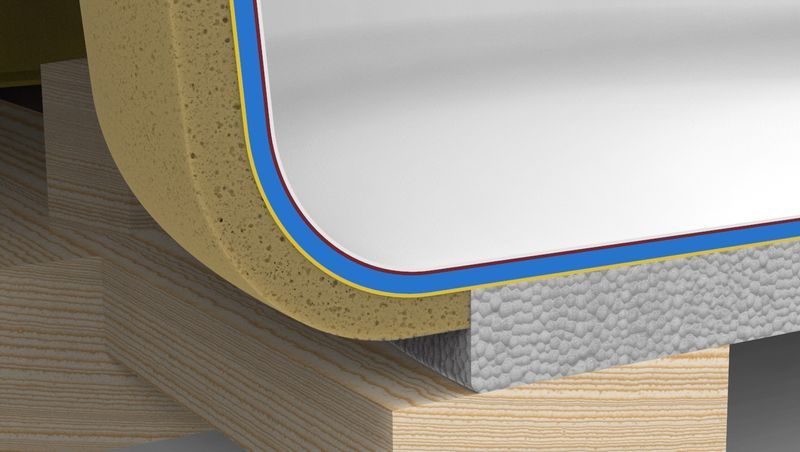

Materials that determine the outcome

The interior of each hot tub mirror is made layer by layer, painstakingly handcrafted exclusively from the same quality materials that, for example, are used in the marine industry to build only the most luxurious megayachts:

- BÜFA® Marine NPG Gelcoat

- BÜFA® VE barrier coat

- Fibreglass and polyester laminates (2,5-3,5 mm)

- Coremat layer to increase strength on horizontal surfaces (3 mm)

- Fibreglass and polyester laminated layer (0,7-1 mm)

Everything that allows yachts to survive the biggest storms and withstand the blazing sun and freezing cold in variable sea conditions makes Lingalaid a hot spring you simply won't find anywhere else.